IndraMotion MTX performance

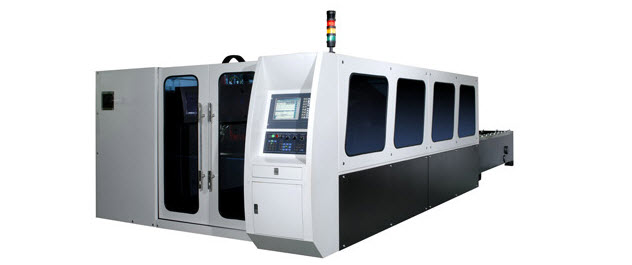

IndraMotion MTX performance, packaged in a special high-end industrial PC with matching operating features, is the cnc system solution of choice for demanding machine tools in harsh industrial environments. The controller delivers excellent performance and offers a wide range of technology functions for special requirements.

![]()

Up to 32 of the 64 axes available can be used for spindle functions. With up to 12 independent CNC channels you can implement the most exacting applications. A whole series of functions is available for performing complex interpolation, axis coupling, special kinematics, fast I/O coupling and much more.

![]()

IndraMotion MTX performance can be upgraded to handle future requirements. For example, you can add additional interfaces or fieldbus connections.

![]()

![]()

| Machining Technologies |

| Turning |

| Milling |

| Drilling |

| Grinding |

| Nibbeling, laser cutting |

| Forming |

| Axis control |

| 8 axes (standard) |

| Expandable to max. 64 axes |

| Max. 32 axes per spindel |

| 3 independent circuits (standard) |

| Expandable to max. 12 independent circuits |

| Max. 4 interpoliating axes per circuit (standard) |

| Expandable to max. 8 interpoliating axes per circuit 7 |

| Linear axes, endless linear axes |

| Circular axes |

| Endlessly rotating cirular axes |

| Hirth axes |

| Spindel/C-axis change-over |

| Max. 8 gantry axes per circuit 2,3 |

| Max. 8 sycronized blocks per circuit 1,2,3 |

| Circuit comprehensive axis transfer |

| Cam |

| Software limit switch |

| Master spindel synchronization 1,2,3 |

| Integrated safety technology cat. 3 according to DIN 954-1 (secure hold, secure reduced speed, secure final position) 6 |

| Interpolation functions |

| Linear interpolation |

| Linear interpolation with/without exact stop before NC block transistion |

| Circular interpolation with radius and center programming, Helix interpolation |

| Circular interpolation with tangental entry |

| Threading drill without compensating chuck |

| Threading cutter |

| optional max. 1000 NC-blocks projection, Look-ahead with jerk limiting |

| 0,25 ms interpolations cycle time, min. with 8 axes |

| 5/6 axes transformation with TCP programming 3 |

| Jog with active transformation 3 |

| Spline interpolation, C1 + C2 continuous, cubic splines, B-splines, NURBS 1,2,3 |

| Nanometer resolution |

| Feed Functions |

| Feed in mm/min or inch/min |

| Time programming |

| Feed per rotation |

| Constant cutting speed 1 |

| Run til positive stop |

| Torque reduction |

| Shift and Corrections |

| Mirroring, scaling, turning |

| Zero shift |

| Corrections and zero shift programmable with PLC |

| Corrections and zero shift programmable with CNC |

| Placements (Frames) 2,3 |

| 2D-course corrections |

| 3D-milling radius correction 3 |

| Course correction with level switch |

| Tangental tool guidance |

| Tool maintenance |

| Integrated, flexible tool maintenance |

| Configurable tool database |

| Freely definable tool corrections (length, radius, cutting- position correction, user data) |

| Additive tool corrections (D-corrections) |

| Access to tool data via the PLC |

| Access to tool data via the CNC |

| CNC-programming |

| Partail program compilation according to DIN ISO 66025/EIA274 |

| High language programming, CPL Customer Programming Language |

| Grafic NC-programming 4,5 |

| Grafic NC-simulation 4,5 |

| 64 MB CNC user memory |

| 8 MB static memory |

| Max. Partial program size dependent on the PC hard drive |

| Technology cycles |

| Drilling 1,2,3 |

| Turning 1,4 |

| Milling 2,3,5 |

| Functions |

| Dwell time in seconds |

| Acceleration programming, KV-programming |

| Referencing via NC-program |

| Absolut dimention, relative dimention |

| Switch inch/mm |

| Sensor input, static/flying measuring |

| Process and drive data readable with SERCOS Interface |

| Rounding and bevels |

| Laser power controler |

| Digitalisation |

| NC-block specification from PLC |

| Support for user intervention |

| Configurable user screens |

| Cycle-header/input support OEM-cycles |

| Block run/block search run |

| Dry run |

| Departure and NC block restart on the contour |

| PLC programming |

| Integrated PLC: IndraLogic |

| Programming languages IEC61131-3 (AWL, KOP, FUP, ST, AS) |

| 8 MB PLC program memoryr |

| optional 8/8 high speed input/output |

| 8KB per fieldbus input/output |

| typ. PLC processing time 60µs per 1.000 commands |

| Multitasking |

| Max. 16 PLC tasks |

| Diagnosis and start-up tool |

| Integrated, system comprehensive engineering framework IndraWorks |

| Automatic system monitoring |

| Indication and error messages in clear text |

| Integrated drive projection |

| Drive oszilloscope |

| Integrated PLC projection |

| Logic analysor |

| optional remote diagnosis |

| Openness |

| Configurable operator panel with all standard functions |

| Projectable, user-defined user screens |

| Adaption and integration over standardized interfaces (OPC, XML, ActiveX, .NET) |

| Optional with open NC-Kernal for the integration of technology functions |

| Conrtol hardware and interfaces |

| CPU: IndraControl P60 |

| Digital drive interface SERCOS interface, 2 - 16 MBaud |

| Profibus DP, 12 MBaud |

| Ethernet, 100 MBit |

| Optional ethernet-IP |

| Optional device net |

| Software and hardware |

| Operating system Windows XP |

| Optional panel-PC IndraControl VSP 16 |

| Optional panel-PC IndraControl VSP 40 |

| Optional panel-PC IndraControl VPP 16 |

| Optional panel-PC IndraControl VPP 40 |

| Optional panel-PC IndraControl VSB 40 |

| Optional panel-PC IndraControl VPB 40 |

1) Requirement technology package "Turning 1"

2) Requirement technology package "Milling 1"

3) Requirement technology package "Milling 2"

4) Requirement shop programming "Turning"

5) Requirement shop programming "Milling"

6) Option in connection with IndraDrive

7) Obligatory export license for this product

In accordance with part I C of the export list (EG-VO) position 2D002.